How Did Watches Get Railroad Approved?

It can be pretty easy to take modern watchmaking standards for granted. Though quartz watchmaking has made standardizing the accuracy of the watch more simple—things weren’t always so easy. With so many mechanical manufacturers throwing their conductor hat into the railroad ring, nailing down accuracy was both a competition and continental collaboration. It took decades of innovation, with a blend of tragedy, in order to make railroad watches the most dialed-in pieces of their heyday. With more widespread use of railways beginning in the mid-19th century as well as an emerging mass-production watch market, the biggest powers behind the railroad industry and watchmaking would eventually align—getting ahead of the curve (in many respects) on global standards of time.

An Historical Timeline

To start, railway timekeeping standards varied from town-to-town and railroad company by railroad company. In the 1850s and 1860s Canadian and U.S. railways were adopting American-made and Swiss watches. Though most wristwatches utilized similar features (bold Arabic numerals and lever-set hands) there wasn’t a true list of specifications to go by. Essentially, folks were winging it in North America. The Canadians would go on to kickstart the first railroad watch standards. Ahead is a pared-down timeline that shows how this emergence evolved into an international affair.

-1850s 1860s: Every township, city, and company had their own standard in the U.S. and Canada. The Canadian Pacific Railroad (CPR) starts building steam on standardizing timekeeping.

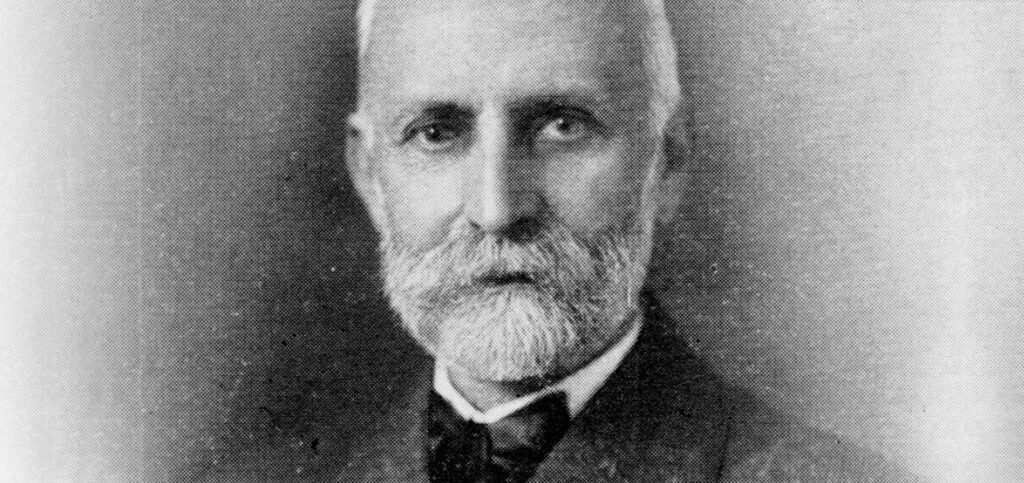

-February 1879: Sir Sanford Fleming (CPR) proposed a Worldwide Standard Time. His proposal comes five years before GMT was established as the international global time standard.

-1880s: The “Canadian Dial” was adopted by the CPR, a precursor to the U.S. Ferguson Dial (patented later). It featured both interior-dial and exterior-dial minute/hour markings—without the red and black contrast of the later Ferguson Dial. This pocket watch resembles modern standard railroad watches and was incredibly innovative

-1893: Arguably the most significant date in this timeline. Webb C. Ball was charged with standardizing North American railway timekeeping. This is due to a tragic railway incident in the American Midwest (1891). The crash involved multiple deaths, due to a four minute loss of time on a conductor’s timepiece. Over 600 rail lines would come to drop their own standards to take on Webb’s.

–Webb’s standards state that a watch needs to “Be open face(d), size 18(mm) or 16(mm), have a minimum of 17 jewels, adjusted to minimum five positions, adjusted to temperatures of 34 to 100 degrees Fahrenheit (-1 to +38 grade Centigrade), steel escape wheel, lever set, micrometric regulation, Lépine caliber.” He goes on to note some variation. “Some Railroads wanted Breguet hairspring, adjusted to isochronism and 30 degree Fahrenheit and minimum of 19 jewels.” (Source: WatchTime). These standards remained unaltered for nearly 40 years. Lever set, rather than watches set on the crown, remained chosen because their crowns would not catch by mistake.

-1904: Railroads and railroad watches have really hit their stride. Railroad companies have whole fleets of quality inspectors checking timepieces for standardized features at every railway stop. Another railway-minded Ferguson invents the “Ferguson Dial”. His name was LB Ferguson (from Monroe, Louisiana). It is still the most popular railroad watch dial, to this day. It was the first U.S. dial design patented for railroad use.

-1930: New standards emerge from RD Montgomery—general railway inspector of the Santa Fe Railway System. This includes a loss or gain of no more than 30 seconds per every 72 hour period. American railway companies “buy American”. Canadian railroad companies stick mostly to Swiss watches, still.

-Mid 20th century: Watchmaker Longines releases the RR280—considered by critics to be a pinnacle watch in railroad standardization. It features a “Ferguson” style dial with all standards met (and exceeded). Because of its primary use in Canada, many refer to it as “The Canadian”.

Standards that Still Appear

Electronic timekeeping in the latter 20th century eventually made accurate timekeeping easier—and more affordable. However, maintenancing mechanicals and constant inspection set new standards in watchmaking that still influence watchmaking to this day. If one comes across a “RR Approved” marked dial, there’s a historically significant quality assurance built into its case. Riding the rails may is far more atomically aided in our modern age. However, human hands and thoughtful engineering laid the track for current accuracy.

Times Ticking has been in operation for more than 30 years, since 1982. We have performed watch repair for customers both locally and internationally. If it Ticks! We KNOW it! Our team of watch repair technicians have a combined experience in watchmaking of over 120 years.