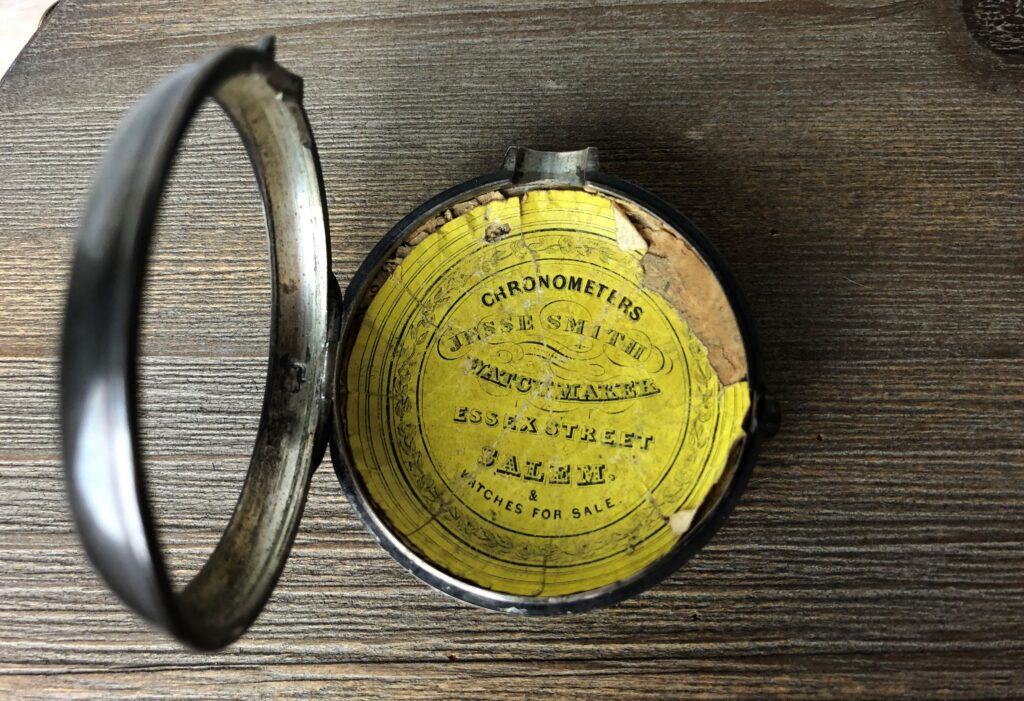

Salem Massachusetts Vintage Watch

Crossing the workbench of our repair shop

recently, we’ve been sent a uniquely American timepiece. In the 19th century

many watchmakers—especially along the East Coast—were hired to manufacture both

watches and marine chronometers. One particular watchmaker made solid work for

himself in the early part of said century. His name is Jesse Smith Jr.. His

work was never mass produced but his craftsmanship lives on. An 1836 piece from

his old shop in Salem is one of the oldest watches we’ve had the pleasure to work

on. Ahead we’re going to talk a little bit about the history of Jesse Smith

Jr’s. career.

Decades

of Work

As history shows, the piece we received for upkeep was built on the culmination of nearly 30 years of work. Jesse Smith Jr’s. apprenticeship began in 1807. This apprenticeship was under the master watchmaker Benjamin Balch. Initial timepieces from Smith are stamped with both his and Balch’s name on the inside of their cases. Reading as “Balch and Smith/Clock and Watch Makers/Salem”, these first collaborative watches began releasing in 1815—eight years after Smith’s career began. One year afterward, Smith began producing his own watches, clocks, and marine chronometers out of Balch’s shop. Each was stamped with Smith’s name and included the shop’s street name, “Essex”. The two would remain partners in their collective endeavors until 1832. With the maritime industry still in plenty of need of chronometer adjustments and timekeepers, Smith did well to keep the shop open.

The watch we received

here at Times Ticking was built four years into Smith’s solo career on Essex St.

in Salem. A decade later (1846) his sons were old enough to begin working in

the family business. Smith was a prominent Freemason and influential figure in

his community until his death. From what we can gather from the history of his

shop, he primarily made mechanicals with fusee spring-wound movements. It’s a

technology indicative of the times.

The fusee movement on the 1836 Jesse Smith Jr. watch we took in is pretty standard fare for this era’s builds. The mainspring is coiled around an arbor (a fixed axle) inside of a barrel (a cylindrically shaped box). The fusee (or mainspring compensator) drives the gear train by pulling momentum generated from the mainspring unwinding—to keep the description brief. Aside from watches, Smith’s work would have also included clock making (likely regulators), watch and clock maintenance, and marine chronometer upkeep for maritime vessels. His expert skills are veritably present in the piece we’re currently maintenancing.

Old School Value

We’re no strangers to old-timey watch tech. Aside from 19th century American pieces, we continually have run-ins with gems from all over the globe. Many of these watches are hiding in plain sight—but have a unique history all on their own. If you or anyone you know has one in the family, or is searching for a hidden antique treasure, it’s well worth it to have them maintenanced once obtained. Their monetary value often far exceeds the cost to repair. But what’s more, giving new life to these pieces keeps the heart beating on historical vignettes in watchmaking. Risking excessive sentimentality—handmade pieces have an individual existence that transcends any price. It is always our pleasure to take special care of every timekeeper, including the vintage pieces that make it through our door.

Times Ticking has been in operation for more than 30 years, since 1982. We have performed watch repair for customers both locally and internationally. If it Ticks! We KNOW it! Our team of watch repair technicians have a combined experience in watchmaking of over 120 years.