The History of The Elgin National Watch Company

The Elgin watch company, founded in 1864, was originally known as the National Watch Company. The idea, for the company, was simple enough, if Massachusetts could build a factory that built watches – Illinois could, too. And so it began, a lofty $100,000 in capital was raised and the company was founded by 7 men; Illinois’ first pharmacist, and an outspoken abolitionist; Philo Carpenter, a bookbinding and stationery business owner; Howard Zoroaster Culver, an American politician who twice served as mayor of Chicago; Benjamin W. Raymond, an American pioneering explorer and cartographer; George M. Wheeler, an investor; Thomas S. Dickerson, an American physician and railroad executive; Edward H. Williams, and a lawyer and judge; Salias W. Robbins. The businessmen informed Elgin, their preferred location, that in order to do business there they required a donation of 35 acres of land and $25,000 from the townspeople. The requested location was on an abandoned farm, because of the American Civil War, which was not for sale unless the entire farm was purchased, the owners stated. Four local, Elgin, businessmen, stepped up and purchased 71 acres of farmland, from the owners, for $3,550, and donated the 35 acres needed for, the National Watch Company, to start the factory, in their town. The company was then re-organized, on April 25, 1865, with additional capitol of $500,000, which was used, to build their watch factory. The project, which took about one year, included lathes and machines to achieve seemingly impossible levels of precision. The first officers were: Raymond, President; Carpenter, Vice President; Dickerson, Treasurer; Wheeler, Secretary.

The idea, for success, was to mass produce high-quality pocket watches using machine-made, interchangeable parts. By today’s standards, this seems like an obvious approach, however, up until about 1850 watches were all made by hand. The company recognized and saw a need for good quality, reliable watches that could be sold and repaired relatively inexpensively using factory made replacement parts. Repaired relatively inexpensive was the key, before this if a watch was damaged replacement parts would need to be manufactured, by hand, to fix the problem. The goal wasn’t to produce the best watches, or the cheapest, but rather to dominate the substantial middle-ground of the watch market, which they did for a number of decades.

In 1864, seven key people, named the Seven Stars, were lured away, from Waltham Watch Co., with the promise of a $5000 bonus, $5,000 per year salary for 5 years and one acre of land on the company’s property. These seven were all machinists first and watchmakers second. Elgin lost several of the Seven Stars, to the Illinois Watch Co., a few years later, in 1869. One of the seven, Charles S. Moseley, who had been in the watch business, since 1952, was the Elgin factory’s first superintendent.

The first movement, Elgin produced, was an 18-size B. W. Raymond model, named for mayor ‘Benjamin W. Raymond’ and the company’s then president, which sold, in April of 1867, for the price of $115. They then introduced the H. Z. Culver, a 15-jewel, adjusted, high grade, full plate movement much like the B.W. Raymond. By the end of the year, they introduced the H. H. Taylor grade which was advertised for use by railroad men. Elgin defined the American pocket watch as unsurpassed in Railroad Accuracy and precision. This kicked off a century of success the company flourished, and prospered, over the next 100 years. In 1869, the National Watch Company won ‘Best Watches, Illinois Manufacture’ at the 17th annual Illinois State Fair.

During the 1870s, the company developed an affordable line of pocket watches for every day working men. The 18-size and 16-size watch models were redesigned as smaller size watches for general use. The prices were reduced resulting in an increase in demand. With their watches being affordable, the factory was now turning out 25,000 watches, each year.

In 1873, the first stem-wind B. W. Raymond movement was placed on the market. The product line included at least 14 different grades and production was estimated at 100,000 movements per year. Elgin became best known for producing the ‘working man’s’ mid-grade watches. Throughout this decade, the prices were reduced resulting in an increase in demand. Yet, they still produced high-grade watches, too. Elgin produced each of their watches with different grades to identify their level of quality. Elgin assigned a grade number to a movement of a specific size, jeweling, and finish. If a change was made a different grade number would be assigned.

The name, National Watch Company, did not stick, as the general public knew them as the ‘watches from Elgin’ so, in 1874, they changed their name to Elgin National Watch Company, which remained. The company sold and marketed watches under the names Elgin, Lord Elgin, and Lady Elgin. Elgin watches were the company’s standard range of watches. Lord Elgin were the luxury range for gentlemen. Lady Elgin were the luxury range for ladies.

In 1910, Elgin engineers built their own two-story Observatory, two blocks from the factory, on the corner of Watch and Raymond Streets, to provide data, on time, that was scientifically accurate to a tenth of a second and help produce a more accurate watch. The observatory was an important part of the company’s legacy and, in 1994, was added to the National Register of Historic Places. The company produced many of the self-winding wristwatch movements made in the United States.

During World War I, the Elgin factory trained 350 men, of the United States Army, how to make precision repairs required in the battlefields, as synchronized watches were key during the war, within the trenches.

By the end of the 1920s, the America watch production had dropped from 1.8 million movements in 1923 to 1.75 million, 5 years later. Imports, mainly from Switzerland, rose during this same period from 2 million to 4.3 million. Of the thirty-five manufacturers which had once been in production, in the U.S., only five were left, including Elgin. Between the world wars, Elgin made numerous beautiful watches including stunning art deco pieces incorporating a range of luxurious components, including white gold cases and jeweled faces.

A trade agreement, with Switzerland and the United States, went into effect on February 15, 1936. Duties on Swiss watches, imported to the U.S., were cut an average of thirty-four percent below the previous 1930 rates. In exchange, the Swiss, in turn, lowered their tariffs on American goods. Prior to this agreement, the American watch industry had fifty-three percent of the American public jeweled watch market. Aided by government subsidies, the Swiss led in technological innovations and the American companies began to lose market share.

From the beginning, the company maintained its general offices, in Chicago, Illinois, however, these were all eventually transferred to the Main Plant, in Elgin, by 1940.

During World War II, the US watch industry was halted and ordered, by the government, to stop all watch production and Elgin immediately moved into the defense industry, manufacturing military watches, chronometers, fuses for artillery shells, altimeters and other aircraft instruments and sapphire bearings used for aiming cannons. In March, 1944, the American watch companies petitioned the government for relief from the avalanche of Swiss imports. Switzerland, officially neutral during World War II and have not taken part in a war since 1505, the longest standing neutral nation in the world, was not ordered to halt production and continued, as normal. During the U.S. halt, the Swiss captured, a whopping, 95% control of the U.S. watch market and had a complete monopoly of the machinery needed to make watches. During the war, the U.S. watch industry had worn out its equipment, from war production, and now needed to replace it but the Swiss factories would only lease them new equipment. American watch companies argued, by renting the equipment, the Swiss will then be able to exert control over foreign watch industries. The U.S. government, in return, did not put such conditions on the sale of American machine tools that the Swiss needed to make their watch machinery, when needed. Walter Cenerazzo, president of the American Watch Workers Union, at the time, pleaded with a congressional committee in Washington, D.C., in May, 1942, for a higher tariff, on Swiss watch imports, stating The United States Government says to the American watch workers: “You cannot produce for civilian use as we need your output for American defense”. We agree the United States Government is correct in doing so, but, on the other hand, the Swiss watch industry is given free reign to ship into the United States an unlimited amount of watches, at total landing costs which are less than our cost of production’. After the war, Elgin, being heavily affected, laid off three hundred workers and went to a four-day week schedule. Elgin Plant No. 3, in Aurora, Illinois, containing 30,370 square feet, closed in 1950.

From 1950 through 1964, again manufacturing watches, Elgin produced 4 automatic wristwatch movements: grades 607, 618, 760, and 761. In 1958, they introduced ‘DuraBalance’, which was a technologically advanced balance wheel incorporated several features. Sadly though, this would not be enough to save the company from extinction.

Going forward, parts of the company ceased to function. The observatory was abandoned, in 1955, and turned over to School District U46 in 1960. The Watch Word, which chronicled personal stories, photos, company history, engineering successes and local businesses for employees, stopped publication, in 1956. The last company earnings dividend was paid, in 1957. In 1958, their Lincoln, Nebraska plant, a 440,000 sq. foot progressive assembly line plant, which then employed eight hundred fifty workers, was shut down and sold to the University of Nebraska, while its operations were consolidated to Elgin, Illinois. The Watchmakers College, which graduated and passed 5,000 students with their Horological Institute examinations, closed its doors in 1960. In an attempt to cut costs, an assembly plant was opened in Blaney, South Carolina, in 1963. Residents, of Blaney, were so eager to land the Elgin factory that they voted to change its name to Elgin in a landslide 61-16 vote. The main plant, in Illinois, supplied the southern operation with parts. When the company observed its centennial in 1964, only about 900 employees were left, in the main factory, in Elgin.

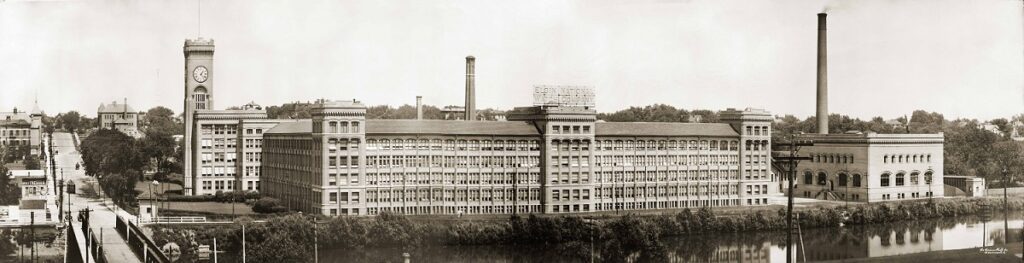

The original factory, Plant No. 1, containing 454,800 square feet, in Elgin, closed in 1964, after having produced half of the total number of pocket watches manufactured in the United States (excluding dollar pocket watches). The factory clock tower had been put out of commission, in late August 1965, and on Oct. 2, 1966, demolished. In 1967, the Elgin, South Carolina plant was sold to B.F. Goodrich. In 1968, the rights to the name ‘Elgin’ were sold and have been resold, many times, since then. Elgin-branded watches produced, after 1968, have no connection to the Elgin National Watch Company. A leased plant, for casing, fitting, shipping, service, materials and offices, in, Elgin, Illinois, was occupied beginning in 1964 when operations were transferred from the obsolete Main Plant to South Carolina closed up in 1970. Plant No. 2, containing 64,930 square feet, also in Elgin, Illinois, was sold, in 1972.

The Elgin National Watch Company factory was once the largest site dedicated to watchmaking in the world. At its peak, it employed over 4500 people, more than half of which were women. During their production run of over 100 years, Elgin produced almost 60 million watches, peaking at over a million watches per year, which is nearly half of all the jeweled watches produced by American watch companies, at that time. They, and their story, are an American historic treasure.

Times Ticking has been in operation for more than 30 years, since 1982. We have performed watch repair for customers both locally and internationally. If it Ticks! We KNOW it! Our team of watch repair technicians have a combined experience in watchmaking of over 120 years.